Komo Machine, Inc. is a well-known American CNC machining center manufacturer, headquartered in Lakewood, New Jersey. KOMO was founded in 1966. Since 1987, KOMO has installed over 3,500 CNC machines worldwide, making it one of the leading CNC router manufacturers in North America. KOMO was acquired by PMC Global Inc. in 1999 and continues to expand its influence in the global market.

KOMO's product line encompasses a wide range of high-precision CNC machining centers, suitable for machining various materials, including wood, plastic, aluminum, and metal. These materials are processed by KOMO's CNC milling machines, such as the KOMO wood CNC machine and the KOMO machine tool.

Its main product series include:

1. Xtreme Series CNC machines

• Xtreme XL CNC machining centers: Designed for cost-effective customers who require high technical quality and reliability, it features a mobile table configuration and side-mounted tool changer.

• Xtreme 5 Axis CNC machining centers: Provides greater machining flexibility and Z-axis travel, equipped with a liquid-cooled spindle, suitable for complex multi-axis machining tasks.

• XTREME 1005TT CNC routers

2. Fusion Series CNC machining center

• Fusion XL: Features greater flexibility, a larger tool changer, and longer Z-axis travel, with a mobile table configuration.

• Fusion Twin Table: Offers a twin table configuration for increased productivity.

• Fusion 5 Axis: Equipped with a high-power liquid-cooled spindle, suitable for complex five-axis machining applications.

3. Mach III Series CNC machining center

• Mach III: Designed for customers who need more options and flexibility, it offers a variety of configurations and accessory options.

• Mach III GT: Equipped with a 15-position automatic tool changer, it supports a variety of processing needs.

• Mach III Twin Table: Available in single or dual table configurations to meet different production needs.

4. Solution Series CNC machining center

• Solution XL: Adopts a mobile gantry structure, suitable for customers who need longer processing lengths.

• Solution Wide: Provides wider and longer processing dimensions to meet the processing needs of large workpieces.

5. VGM Series CNC machining center

• VGM: Designed for customers who need to process ferrous and non-ferrous metals, it has a heavy-duty structure and is suitable for high-intensity processing tasks.

In order to keep the KOMO CNC machine running normally and reduce downtime, it is very important to replace common-wearing parts in time. As the machine runs for a long time, some parts gradually wear out due to frequent use, especially in a high-intensity industrial environment. Here we introduce 8 parts that often need to be replaced on KOMO CNC machines.

76mm Long HSK 63F tool holder, KOMO 101453-00

115mm long HSK 63F Tool Holder, KOMO 102190-00

BT30 tool holder

60mm long BT30 Taper tool holder, KOMO 063854-00

90mm long 30 Taper Tool Holder, KOMO 100462-00

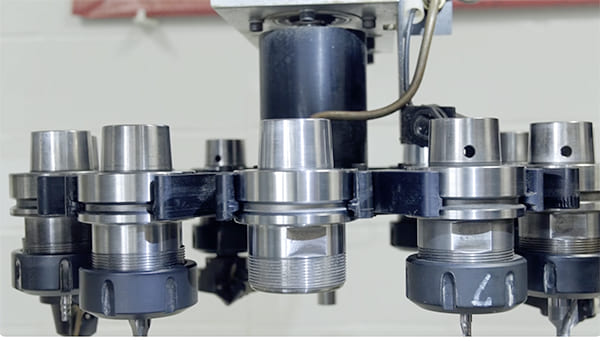

2.CNC tool gripper

HSK63F tool gripper, KOMO 101718-00 HSK Clamp Set

BT30 tool gripper, KOMO 061593-00

3. CNC collets

ER32 collet

ER40 collets

BT30 Retention knob, metric, KOMO 062877-00

5. HSK 63F Tightening Stand, KOMO 106750-00

Fly cutter KOMO 102615-00

Replacement Inserts for KOMO fly cutter, 102616-00

7.CNC drilling bits

Timely replacement of common KOMO machine parts not only helps to extend the service life of the machine but also improves processing efficiency and avoids losses caused by unexpected downtime. RicoCNC specializes in providing high-quality CNC accessories and tools for many brands of CNC machines, with many years of industry experience and a full range of CNC machine accessories. If you are looking for KOMO CNC parts or KOMO router parts, welcome to contact us!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665