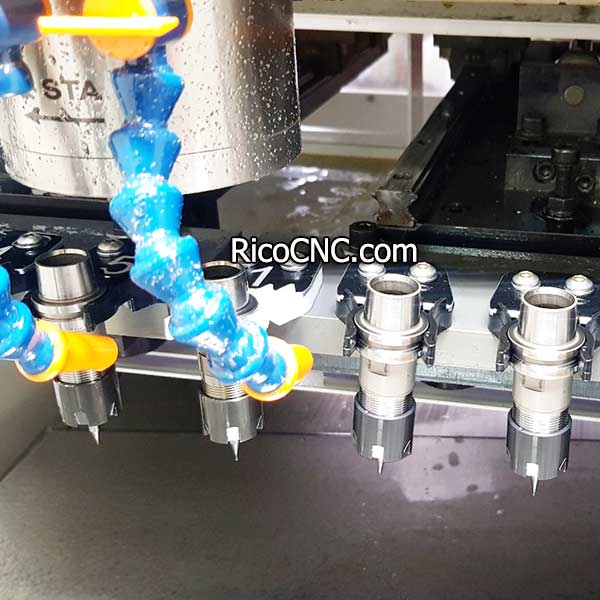

HSK25E Tool Holding Forks Plastic Clip Fingers for ATC CNC Milling Machine

This plastic tool holder finger is HSK 25E toolholder clip. It is used for HSK E25 tool holders clamping. The HSK25E fork fits for all HSK 25E toolholders.

As HSK25 tool holder is small and light, great performance for high speed machining, so the hsk e25 tool gripper widely used with automatic tool changer CNC machines, such as cnc engraving machine, CNC milling machine, VMC (Vertical Machining Center), etc.

RicoCNC is a good source for CNC manufacturers who use HSK25E tool for the CNC system. So need its plastic clips on the tool holder. Also a reliable supplier for CNC users.

HSK25E Tool Fork Specifications:

1. Made in China, a famous brand.

2. Imported POM plastic material, high quality, reinforced and anti-explosion.

3. Dynamic balance grade: G2.5, 30000rpm

4. Yaw precision: 0.005mm

HSK25 Replacement Tool Clips Application:

1. Apply for auto tool changer CNC machine tool magazine, drum-type, carousel-type, etc.

2. Application industry: CNC hole drilling, CNC milling, CNC engraving, high precision and widely used for high precision processing.

HSK 25E plastic finger clips are available in stock for quick delivery.

Rico CNC supplies a large range of high-quality CNC machine spare parts, consumables, replacement and accessories. ISO tool clips (ISO40-ISO30-ISO25-ISO20- ISO10), HSK tool forks (HSK63F-HSK40E-HSK32E-HSK25E), BT tool grippers (BT50-BT40-BT30), CNC replacing tool changer forks for many auto tool changers CNC machines.

Payment can be made by Western Union, Paypal, T/T.

Welcome your inquiry!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665