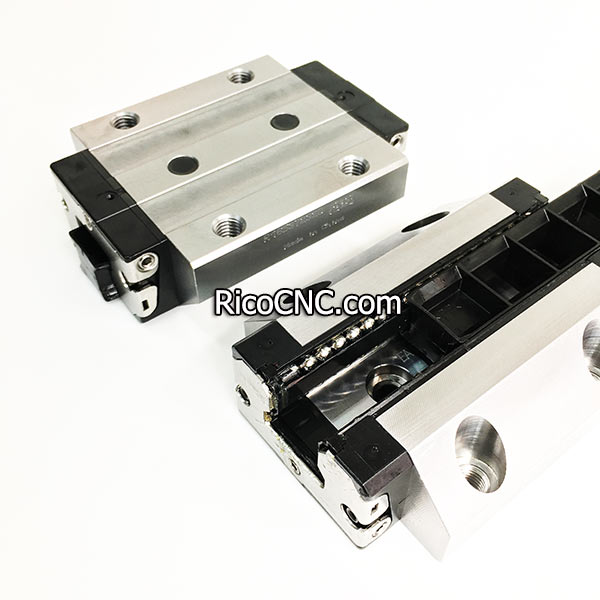

Bosch Rexroth Linear Ball Runner Blocks R165372320 KWD-030-FLS-C2-H-1

Bosch Rexroth linear R165372320 is ball runner block CS KWD-030-FLS-C2-H-1. Bosch Rexroth ball runner blocks FLS, flanged, long, standard height.

Bosch Rexroth linear ball runner blocks R165372320 apply to the most demanding rigidity requirements. Significantly reduced frictional oscillations and low friction level, particularly under external load.

R 165372320 Rexroth Linear Bearing Features:

Can be used on all SNS/SNO Ball Guide Rails

Integrated all-around sealing

High torque capacity

Different preload classes

Maximum precision

Excellent dynamic characteristics

Significantly reduced frictional oscillations and low friction level, particularly under external load

Patented entry zone increases the travel accuracy up to a factor of six

The same high load ratings in all four main directions of loading

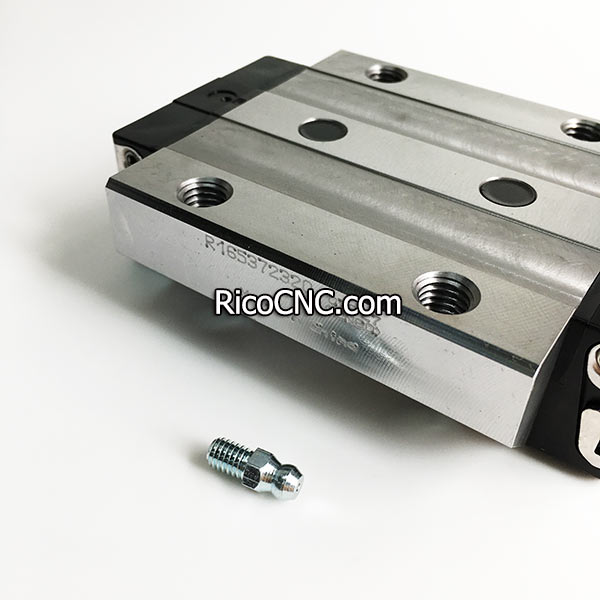

Lube fittings with metal threads on all sides

Ball Runner Block pre-lubricated at the factory.

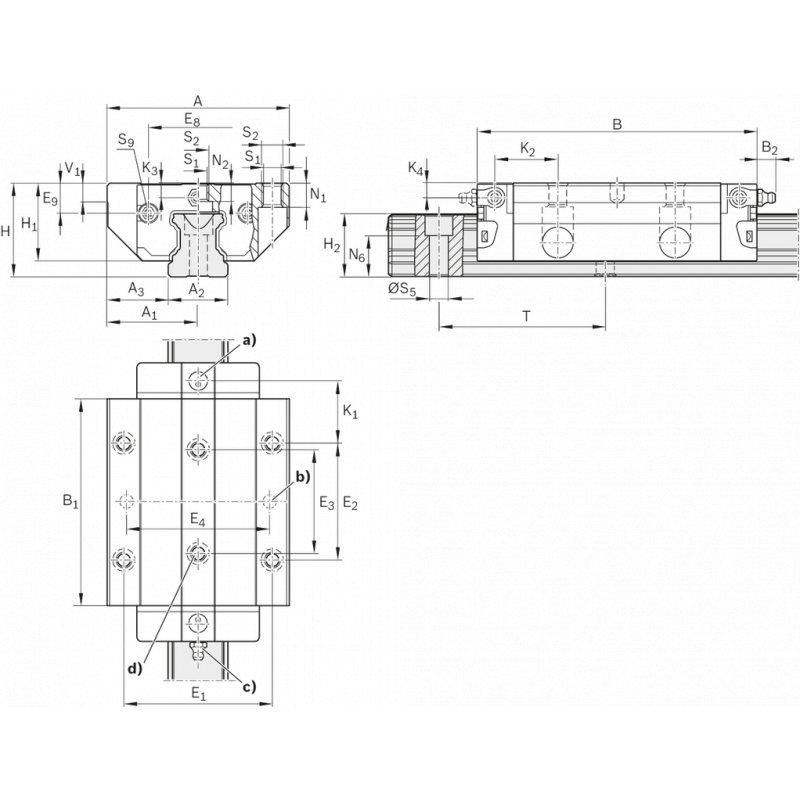

KWD-030-FLS-C2-H-1 Dimension:

a) For O-ring

Size 15: Ø 4 • 1.0 (mm)

Size 20 - 45: Ø 5 • 1.0 (mm)

Open lube port if necessary (see general technical notes and information in the "Maintenance" section).

b) Recommended position for pin holes (dimension E4 see general technical notes and information in the "Installation" section)

Rough-drilled holes may be present here from manufacturing. These may be bored open.

c) Lube nipple, size 15 - 20:

Funnel-type lube nipple DIN 3405-A M3x5, B2 = 1.6 mm

When using different lube nipples, pay attention to the screw-in depth of 5 mm!

Lube nipple, size 25 - 45:

Hydraulic-type lube nipple DIN 71412-A M6x8, B2 = 9.5 mm

When using different lube nipples, pay attention to the screw-in depth of 8 mm!

The lube nipple is included in the scope of delivery (not installed).

Connection possible on all sides.

d) Sealing plugs may be present here from manufacturing. Remove before mounting.

A | 90 mm | Dimension H2 | 28.55 mm | |

A2 | 28 mm | A3 | 31 mm | |

B | 119.7 mm +0.5 | B1 | 89.4 mm | |

E1 | 72 mm | E2 | 52 mm | |

E3 | 44 mm | E8 | 48.4 mm | |

E9 | 14.6 mm | H | 42 mm | |

H1 | 35.35 mm | A1 | 45 mm | |

K1 | 25 mm | Dimension H2 | 28.35 mm | |

K2 | 26.7 mm | K3 | 6.05 mm | |

K4 | 6.05 mm | N1 | 11 mm | |

N2 | 7.9 mm | N6 | 17 mm ±0.5 | |

S1 | 8.5 mm | S2 | M10 | |

ØS5 | 9 mm | S9 | M3x5 | |

T | 80 mm | V1 | 7 mm |

Technical Data:

amax (If Fcomb > 2.8 • Fpr : amax = 50 m/s2) | 500 m/s² | vmax | 5 m/s | ||

m | 1.5 kg | m (Without friction of seal) | 0,002 ... 0,003 kg | ||

Operating conditions | Operating conditions | Size | 30 | ||

Permissible ambient temperature (min ... max) (Up to 100 °C permissible for short periods. For operation at negative temperatures, please consult us. ) | -10 °C ... +80 °C | ||||

Size | Accuracy | Part numbers for runner blocks | |||

up to approx. | Preload | Preload | Preload | ||

30 | UP | - | R165371920 | R165372920 | R165373920 |

SP | - | R165371120 | R165372120 | R165373120 | |

P | - | R165371220 | R165372220 | R165373220 | |

H | R165379320 | R165371320 | R165372320 | - | |

N | R165379420 | R165371420 | R165372420 | - | |

RicoCNC supplies a range of linear guide block and rails brands such as Rexroth, INA, THK, HIWIN, PMI, ABBA, STAF, etc. All are original motion products.

If any need of CNC machine parts, welcome to contact us.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665