THK HSV30 Linear Motion Guide HSR-A Block HSR30A1SS Block

This THK HSR30A1SS linear bearing is standard size flange type THK linear bearing block, also called HSV30. HSV30 linear bearing in China are marked HSR30.

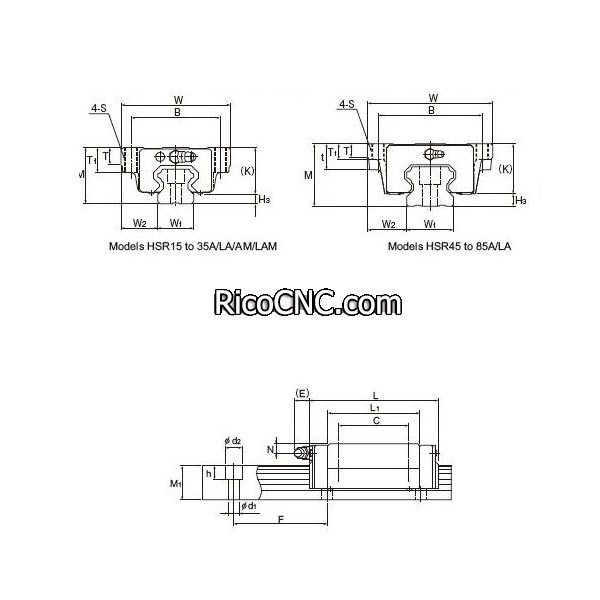

The THK HSR Series of linear motion guides (also known as "LM guides") incorporate linear rolling motion for practical use.

This linear motion guide series can be implemented in all orientations because of this feature. Because this is a full-ball type series, it offered in a wide range of sizes to fit a number of applications, from large scale to small.

THK HSR30A1SS Block Specification:

Part Number | HSR30A1SSC1 BLOCK | |

Rolling Element | Balls | |

Block Type | A | |

Outer(mm) | Height M | 42 |

Width W | 90 | |

Length L | 98 | |

Block(mm) | B | 72 |

C | 52 | |

S | M10 | |

Rail(mm) | Pitch F | 80 |

d1xd2xh | 9x14x12 | |

Basic load rating(Radial) | Dynamic rating C (kN) | 40.5 |

Static rating C0 (kN) | 53.7 | |

Preload | Light Preload | |

Seals | end seals + side seals + inner seals | |

RicoCNC also can supply HSR Series include HSR8, HSR10, HSR12, HSR15, HSR20, HSR25, HSR30, HSR35, HSR45 & HSR55, rail and block lengths range from 160mm to 1600mm. A variety of mounting options are available by choosing the HSR Blocks, which come with tapped screw holes in varying configurations.

RicoCNC is a reliable source for high quality CNC machine spare parts and toolings, welcome to your inquiry.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665