A CNC router is an important and indispensable machine in the woodworking industry, it can help us finish cutting, milling, engraving, drilling, and slotting tasks with precision and efficiency according to design drawing. It also has the unique wearing spare parts except the automatic CNC spare parts, in this article, we'll talk about the CNC router wearing spare parts. It is necessary to know about it if you are in the woodworking industry.

CNC router bits, also called CNC router tools, CNC cutting tools.

The number of CNC router bit's flutes impacts the work speed and the surface finish of the workpiece. If you have some more flutes, First, it adds to the strength of the router bit, which means the bit can be fed into the workpiece faster and work on harder material. Secondly, bits with more flutes offer a better surface finish.

We have the one flute CNC one router bits, three flutes, four flute router bits,

There are two common types of flutes: straight flute CNC router bits and spiral router bits.

Upcut Spiral flute Router bits and Downcut Spiral flute Router bits: determine the direction in which chips are evacuated.

Upcut Spiral flutes Router bits: it pull chips away from the workpiece being cut. An upcut bit tends to leave a rough surface finish on the top of the workpiece and a smooth surface on the bottom.

A spiral down-cut bit, however, pushes chips down as it's cutting.

Here below is our normal router bit's introduction:

Normally we use Tiger T008 CNC router tools, which belong to 3 straight flutes TCT router bits, it can cut Plywood cutting router bits.

They can be used for all boards with all functions, especially excellent performance in cutting laminate boards.

T007 series CNC nesting bits, 3 flutes chip-breaker TCT router bits, chip-breaker. The cutting tool features specially designed notches along its cutting edges.

Chip Breaking router bits, can break long, continuous chips produced during machining into smaller, more manageable segments. This is essential for efficient chip evacuation, improved surface finish, and protection of the tool and workpiece.

T011 TCT router bits are specially designed for melamine laminated wooden board nesting cutting.

CNC tool holders are also called tool holders, CNC milling toolholders, collet chucks, tool holder cones, and collet milling chucks, It is the bridge between the CNC spindle and the CNC cutting tool. The CNC spindle operates the cutting bits and controls the precision process. A tool holder provides the necessary power between these two components. High precision tool holders can keep your CNC machine in a good perofrmanaceCNC tool holders can hold a cutting tool in a precise location. Even some CNC tool holder has a high accuracy and a firm grip. We usually see CAT series tool holders, ISO series tool holders, HSK series tool holders, BT series tool holders, BBT series tool holders, etc.

3. CNC Collet, CNC collets, CNC Router Chuck

CNC collets are an essential component, they are used in clamping systems around the world, their applications include boring, milling, reaming, tapping, and grinding. CNC collet is responsible for holding the tool in place and ensuring precision and accuracy in the cutting process. There are several types of CNC collets available. It has ER spring collets, like ER8, ER11, ER16, ER20, ER25, ER32, ER40 Collet; OZ spring collet system, OZ collet also called EOC, RDO, SYOZ collet, like OZ25-11mm, OZ25-12mm, OZ25-13mm, OZ25-15mm, OZ25-18mm, OZ25-20mm, OZ25-24mm, OZ25-1/2”.

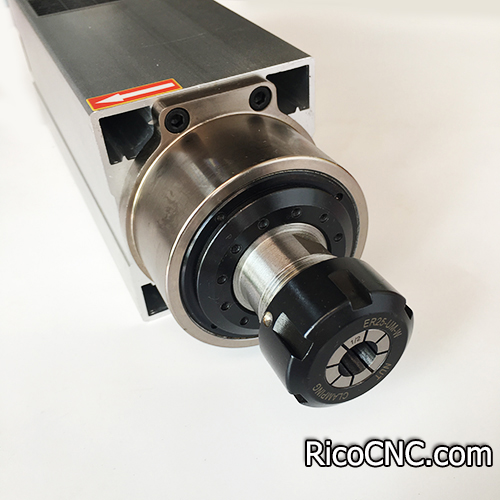

4. CNC spindle:

CNC spindle, CNC spindle motor, CNC router spindle motor, CNC machine spindle, spindle for CNC router, CNC ATC spindle motor, High-Speed Motor Spindle, electro-spindle

The spindle is one of the core components of the CNC router machine. It is used to drive CNC router bits to rotate at high speed for carving. Air-cooled spindles(air-cooling spindles) and water-cooled spindles(water-cooling spindles) are common spindles. The air-cooled spindle structure is simple and the cost is low; the water-cooled spindle is suitable for long-term high-load work, but it needs to be equipped with a water-cooling system.

CNC tool forks (CNC tool clips, tool holder forks, tool finger forks, Tool Holder Clamp Claw Clips, CNC tool Gripper Clamping Forks), The tool magazine is used to fit in various CNC router bits, while the tool magazine can automatically change CNC router bits during CNC router machine work to improve processing efficiency. The tool forks are the important components in the tool magazine. It is used to hold the router bits. normally we can see HSK63 tool forks, Deta BT40,HSK63 tool forks, BT40 tool forks, ISO30 tool clips.

6. Vacuum CNC blocks

Vacuum CNC blocks (also called vacuum pods, Vacuum Suction Cups, or CNC vacuum cups)

CNC vacuum pods are used to fix wood so that the material will not move during the CNC router machine work, then assist the CNC router machine make ensure accuracy. Vacuum suction cups are available in a variety of sizes and materials. for example, Biesse vacuum pods, Homag vacuum pods,

Besides, we also have the it is accessories, like a Vacuum Pad, rubber gasket, etc.

Besides the above accessories, a CNC router also needs some automatic drive system, like a servo motor, servo drive, cylinder, and solenoid valve. If you need any accessories or woodworking parts, contact RicoCNC, here is a one-stop woodworking shop, and we’ll try our best to help you solve the machine troubleshooting. Thanks.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665