PMI MSA30LESSFC Linear Guideways Runner Block MSA30LE Linear Bearing

The linear guideways runner is PMI MSA30LESSFC slider bearing, size 28x90x42mm. Standard bearing steel PMI MSA 30 LE SS FCN PMI linear guide, widely used in linear motion system for CNC machines such as CNC router, CNC milling machine, CNC laser, CNC plasma, etc.

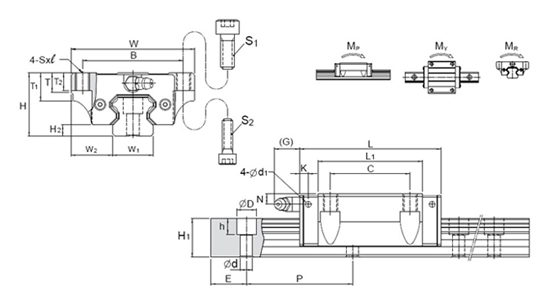

All dimensions are same as MSA-E except the length is longer, which makes it more rigid.

Number of scroll columns: Double row

Rolling bearing housing material: Bearing steel

MSA30LESSFC Linear Block Characteristics:

• High Rigidity, Four-way Equal Load • Self Alignment Capability

• Smooth Movement with Low Noise • Interchangeability

More PMI linear bearing models can be found in RicoCNC:

Model No. | External dimension | Carriage dimension | ||||||||||||||||

H | W | L | W2 | H2 | B | C | S × l | L1 | T | T1 | T2 | N | G | K | d1 | Grease Nipple | ||

H | W | L | ||||||||||||||||

MSA 15E | 24 | 47 | 56.3 | 16 | 4.2 | 38 | 30 | M5 × 7 | 39.3 | 7 | 11 | 7 | 4.3 | 7 | 3.2 | 3.3 | G-M4 | |

MSA 20E | 30 | 63 | 72.9 | 21.5 | 5 | 53 | 40 | M6 × 10 | 51.3 | 7 | 10 | 10 | 5 | 12 | 5.8 | 3.3 | G-M6 | |

MSA 20LE | 88.8 | 67.2 | ||||||||||||||||

36 | 70 | 81.6 | 23.5 | 6.5 | 57 | 45 | M8 × 10 | 59 | 11 | 16 | 10 | 6 | 12 | 5.8 | 3.3 | G-M6 | ||

MSA 25LE | 100.6 | 78 | ||||||||||||||||

42 | 90 | 97 | 31 | 8 | 72 | 52 | M10 × 10 | 71.4 | 11 | 18 | 10 | 7 | 12 | 6.8 | 3.3 | G-M6 | ||

MSA 30LE | 119.2 | 93.6 | ||||||||||||||||

MSA 35E | 48 | 100 | 111.2 | 33 | 9.5 | 82 | 62 | M10 × 13 | 81 | 13 | 21 | 13 | 8 | 11.5 | 8.6 | 3.3 | G-M6 | |

MSA 35LE | 136.6 | 106.4 | ||||||||||||||||

MSA 45E | 60 | 120 | 137.7 | 37.5 | 10 | 100 | 80 | M12 × 15 | 102.5 | 13 | 25 | 15 | 10 | 13.5 | 10.6 | 3.3 | G-PT 1/8 | |

MSA 45LE | 169.5 | 134.3 | ||||||||||||||||

MSA 55E | 70 | 140 | 161.5 | 43.5 | 13 | 116 | 95 | M14 × 17 | 119.5 | 19 | 32 | 17 | 11 | 13.5 | 8.9 | 3.3 | G-PT 1/8 | |

MSA 55LE | 199.5 | 157.5 | ||||||||||||||||

MSA 65E | 90 | 170 | 199 | 53.5 | 15 | 142 | 110 | M16 × 23 | 149 | 21.5 | 37 | 23 | 19 | 13.5 | 8.9 | 3.3 | G-PT 1/8 | |

MSA 65LE | 253 | 203 | ||||||||||||||||

RicoCNC also supplies a range of linear guide block and rails brands also bearings such as Rexroth, THK, HIWIN, PMI, INA, ABBA, STAF, NSK, NTN, FAG, etc. All are original motion products.

If any need of CNC machine parts and tools, welcome to contact us.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665