Linear bearings(also called Linear Bearings, linear bearing blocks, linear roller & ball bearings, linear guide blocks, guide rail carriage, and linear guide sliders) help two parts achieve straight-line motion. It can smooth and efficient movement by reducing friction and wear between moving parts. Linear bearings can be widely used in industrial machinery and automation systems, medical equipment, and consumer products. in this article, we'll talk about the the basic knowledge of linear bearing block.

Linear Guide Blocks Type:

Linear Roller Bearings: The load-carrying capacity and rigidity are the priority for heavy-duty applications.

Linear Ball Bearing blocks: linear ball bearings can reduce friction for seamless motion. They are priority choices in moderate load capacity and high precision. In the linear ball bearing blocks, we usually have: flanged type linear guide blocks and square linear guide blocks.

Linear Ball Bearing Blocks Type according to the Shape:

Flanged type linear guide blocks:

The flange-type linear guide block is lower in height and wider in width compared with the standard-size linear bearing lock. Its mounting holes are through-threaded holes. Like INA Linear Bearing Block KWVE30-B-L-V2-G3.

Square linear bearing block: it can divided into higher square linear bearing blocks and lower square linear bearing blocks. Their height is higher, and their width is relatively narrower compared with flange-type linear bearing blocks. The mounting holes are threaded blind holes.

Linear Guide Blocks Type based according to the loading:

Miniature Linear Bearings: Generally there are 2 rows of steel balls, They are compact in structure and it is suitable for light-load applications, such as precision instruments.

Moderate linear bearing: Usually it has 4 rows of steel balls, which increase the load capacity. They are suitable for medium-load applications, such as general machine tools and automated production lines. Most of the industry manufacturers use moderate loading linear guide blocks. For example KWVE30-B-SL-V2-G2.

Heavy-duty linear bearing: Heavy-load linear guide blocks: Have higher load capacity and rigidity compared with moderate linear bearing, they are used for heavy-load applications, such as aerospace equipment.

Linear Guide Blocks Application:

Linear bearing blocks are crucial in various industries, allowing for precise and seamless linear motion.

They are widely used in industrial machinery, automation systems, robotics, and other applications.

CNC machine Industry:

CNC Milling Machine use linear bearing block to support and position the spindle and tool holding devices

CNC Lathe use linear bearing block supports the linear motion of the tool post to achieving precise turning processes.

CNC Grinding Machine use linear bearing block to support and position the grinding head

Automated Production Lines: you can see the bearing blocks on conveyor belts, robotic arms, and assembly robots.

Also it can be used in robotic Systems, logistics Equipment, etc.

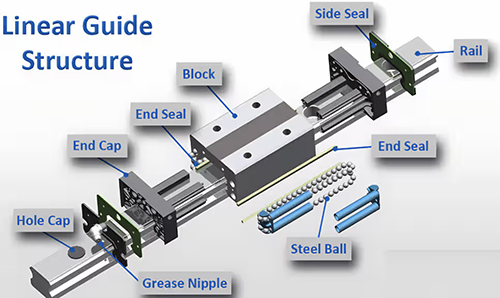

Accessories of linear ball bearing block:

It is made of seal kits, scraper kits, lubrication kits

Seal Kits – these can prevent the extra substances or dust from the bearing inside, seal kits can extend its performance and life

Scraper Kits – They can protect the bearing in dirty or abrasive environments; also they can clear the rail during work any trash or objects. To make sure when the linear bearing block arrives at the place, there is no objectionable debris.

Lubrication Kits – It can be convenient to pour the lubrication into the blocks, it is more convenient to shorten the maintenance time.

How to recognize the linear bearing block model?

For example: HGW25CAEZAP ZZ/E2

From the linear bearing block, it is easy to find that HG series, W shape, 25mm width of the linear guide rail, preload is ZA, precision is P.

No matter which manufacturer you use, model, preload and precision are your priority.

In RicoCNC, we usually offer various internal famous brand linear bearing blocks, like INA, Schaeffler, Bosch Rexroth, Hiwin, THK, ABBA, PMI, and other brands. If you are looking for them, welcome to contact us.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665