When it comes to projects involving foam cutting, choosing the right router bit is crucial. Whether you're a hobbyist making creative DIY projects or a professional working in an industrial setting, using the correct foam router bit can make a significant difference in both the quality of the finished product and the efficiency of the process. In this guide, we will explore the different types of router bits suitable for foam cutting, what factors to consider when selecting them, and how you can enhance your CNC operations for the best results.

Foam materials, whether they are polystyrene, polyurethane, or polyethylene, present a unique challenge when cutting. Unlike wood or metals, foam is soft, compressible, and prone to melting or chipping if the wrong tools are used. Therefore, using specialized router bits helps maintain smooth and clean cuts while avoiding excessive friction. It's all about precision and efficiency. Selecting the right foam cutting router bit allows you to minimize waste, improve the appearance of cuts, and reduce the wear on your CNC router.

The first consideration when choosing a router bit for foam is understanding the type of foam you are cutting. Is it a closed-cell or open-cell foam? For instance, closed-cell foam requires a router bit that can make clean passes without causing the foam to crumble. Using a bit with spiral up-cut features can help pull the material away from the bit, keeping the cutting area clean.

· Closed-Cell Foam: Best cut with spiral flute bits, which help manage the high friction that often results in melted or torn edges.

· Open-Cell Foam: It tends to be less dense and requires a router bit that can easily pass through without creating jagged or uneven cuts.

Selecting the right material type often involves balancing sharpness, feed rate, and spindle speed. Always ensure your bit can efficiently handle the type of foam to prevent uneven or damaged cuts.

Router bits come in a wide variety of configurations, and choosing the best one can seem daunting. Here, we simplify the selection by focusing on the most common router bits used for foam cutting.

Straight flute bits are suitable for relatively soft foam. They provide a clean, straight edge, making them perfect for projects where accuracy and visual appeal are paramount.

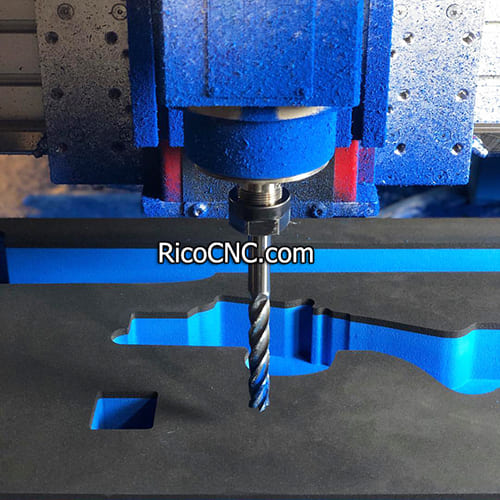

Spiral router bits with multi-flutes are used when cutting or engraving on the foam. They are great for chips removing. They work best in applications where the appearance of the finished piece is critical, such as exhibition displays or packaging prototypes.

Router bit size and length play significant roles in determining the efficiency and safety of your CNC foam cutting projects. A longer bit is more likely to create vibrations, which may affect precision, whereas a bit that's too short could limit the depth you can achieve. Therefore, selecting a bit of an appropriate length and diameter is crucial, considering factors such as:

· Depth of cut needed

· Material hardness

· Spindle speed limits

For best results, always choose a bit that complements the capabilities of your CNC machine.

Feed rate and spindle speed are often neglected but equally important aspects of achieving optimal cuts with foam. When the router bit interacts with the foam, controlling the feed rate (the speed at which the material moves through the cutter) and the spindle speed (the speed at which the bit spins) can drastically affect the quality.

· Spindle Speed: Too high spindle speeds can create excessive friction, leading to melted foam edges. Aim for a moderate speed to keep the bit moving without overheating.

· Feed Rate: A higher feed rate can help reduce heat generation, but this must be balanced to ensure that the router bit isn't moving so fast that it tears the foam.

Foam is often the material of choice for artistic and creative DIY projects due to its ease of handling and affordability. Router bits like ball-nose bits can be used to create intricate details and smooth contours.

Using CNC routers and foam, it is possible to make anything from decorations to sculptures. In these projects, the sharpness of the bit becomes important because an unsharp bit will tear the foam rather than create clean lines.

Foam cutting also plays a significant role in industrial settings, such as manufacturing packaging inserts or architectural models. Here, precision is of utmost importance, and the choice of router bit is even more critical. Router bits used in these situations are often coated to withstand wear over time, ensuring they last longer under frequent usage.

· Packaging Foam: Straight flute or compression bits work best for packaging inserts, ensuring that the foam has a clean edge that tightly holds the items in place.

· Architectural Models: When creating scale models, a fine router bit is essential for cutting out small, precise details without causing the foam to chip.

One of the most common challenges when using router bits with foam is melting. Melting usually occurs due to excessive friction between the bit and foam material. To avoid this, you need to:

· Reduce spindle speed

· Use appropriate cooling techniques like compressed air

Another approach is to use router bits specifically designed for foam cutting, which minimize friction through unique geometry.

Uneven or jagged edges can significantly affect the quality of the final product. This typically results from using dull bits or incorrect feed rates. Always check that your bit is sharp and properly matched to the foam density.

Also, improper router stability can lead to jagged edges. Using products like solenoid valves to maintain CNC stability can provide consistent and smooth edges across the foam surface.

Cutting foam involves an extensive interaction between the router bit and material, making bit wear a potential problem. To maximize bit life:

· Use coated bits for added durability

· Properly maintain bits after each use by cleaning away foam residue

For dense foam, spiral up-cut bits are usually the best choice as they help efficiently remove material while preventing overheating and melting.

Reducing spindle speed, using specialized foam-cutting bits, and adding compressed air to cool the bit during cutting are effective methods to reduce melting.

The feed rate can vary depending on the foam's density, but a faster feed rate generally works best to avoid heat buildup. Start with around 100 inches per minute and adjust as necessary.

Wood router bits can work, but it's better to use bits specifically designed for foam to get the best results and avoid issues like melting or chipping.

A standard CNC router works well for foam cutting, but it's essential to optimize the spindle speed and feed rate for the foam material.

Compression bits offer the smoothest edge by compressing the foam during the cut, minimizing tear-out and producing clean finishes.

Choosing the right foam cutting router bit for your project makes a huge difference in both the quality of your output and the ease of the cutting process. By understanding foam types, router bit configurations, feed rates, and spindle speeds, you can confidently approach your foam cutting projects and achieve clean, precise results every time. Additionally, leveraging tools like CNC routers and maintaining well-selected accessories like servo drives and solenoid valves enhances the quality and consistency of your work.

Feel free to explore more related products and expand your cutting capabilities at RicoCNC. Understanding the variety of wood lathe tools, router bits, tool forks will help your project to the next level.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665