Cutting foam is a task that demands precision and an understanding of the right tools to use. EVA foam, polystyrene, and polyurethane are popular materials used in a variety of applications—from creative projects like costumes to industrial uses such as packaging inserts. One of the key questions that often arises is, can you cut foam with a router bit? The simple answer is yes, and with the right approach and setup, it can be highly effective. This article will delve into how to use router bits to cut foam, the best techniques to apply, and tips for achieving the cleanest and most efficient cuts.

Router bits are versatile tools that have traditionally been used in woodworking for creating grooves, trimming edges, and adding decorative profiles. However, they have also proven to be very effective for cutting foam. The softness and pliability of foam can be easily shaped using a router, allowing for precision cuts and complex shapes that would be much harder to achieve with traditional blades or manual cutting tools.

Straight bits are ideal for creating clean and straight grooves in foam. They are particularly useful when making long, continuous cuts or creating channels in thicker foam.

· Applications: Perfect for creating channels or hollowing out large sections.

· Material Compatibility: Suitable for a wide variety of foam types including EVA foam and expanded polystyrene.

· Tips: Use a sharp, carbide-tipped bit to ensure a clean cut and reduce tear-outs.

Ball nose bits are used when the goal is to create a rounded groove or contour in the foam. Their rounded profile helps produce smooth, consistent edges, which are ideal for detailed foam modeling.

· Applications: Perfect for adding rounded contours or for projects that require detailed shaping.

· Smooth Finish: Ball nose bits reduce the risk of jagged edges, offering a polished finish.

· Best Practices: A slower feed rate is recommended for intricate designs to prevent tearing and ensure smooth contours.

Compression bits combine both up-cut and down-cut features, making them ideal for reducing fraying on both sides of the foam. These bits are best for achieving a smooth finish on the top and bottom surfaces.

· Dual Cutting: The up-cut removes the material while the down-cut ensures the foam stays compressed, thereby preventing fraying.

· Applications: Suitable for packaging foam or when you need both sides of the foam to have a smooth edge.

Router bits come with different shank sizes, typically 1/4-inch and 1/2-inch. Choosing the appropriate shank size for cutting foam depends on the type of cut you need, the density of the foam, and the precision you desire.

· 1/4-inch Shank: Suitable for lighter, handheld routers and small projects that involve soft foam.

· 1/2-inch Shank: Offers greater stability and is preferred for more demanding foam projects that require more precise cuts with minimal vibration.

EVA foam is a flexible, closed-cell foam used in many creative applications. CNC routers and router bits can be used to make precise cuts, intricate patterns, and complex designs in EVA foam.

· Advantages: EVA foam responds well to moderate spindle speeds and allows for smooth, detailed cutting without tearing.

· Applications: Frequently used for crafting, cosplay, and protective gear.

EPS foam is lightweight and easy to cut. Router bits are often used to shape EPS for insulation panels, model making, and other large foam structures.

· Cutting Tips: Use a slower spindle speed to prevent melting and use sharp bits to avoid tearing or jagged edges.

Polyurethane foam can also be effectively cut using router bits. Its consistency makes it suitable for applications such as padding, prototyping, and model building.

· Care: Polyurethane foam can easily compress, so use a steady, consistent feed rate and avoid applying too much pressure.

One of the most critical factors when cutting foam with a router bit is setting the right spindle speed and feed rate. These settings help control how much friction is generated during the cutting process and therefore impact the quality of the cut.

· Spindle Speed: Foam is prone to melting if the spindle speed is too high. For foam, it’s best to use a moderate spindle speed—around 12,000 RPM for most foam types.

· Feed Rate: Using a high feed rate can help minimize friction and prevent the foam from melting. Starting with 100 inches per minute is a good baseline for most foam materials.

Foam can melt under the friction generated by router bits, which can result in rough or uneven cuts. Utilizing compressed air to cool the foam while cutting helps maintain a lower temperature and improves the overall quality of the cut.

Using a router bit to cut foam provides a level of precision and control that cannot be matched by manual tools. This is particularly useful for creating detailed designs, sharp edges, and consistent cuts.

Router bits can be used for various foam-related projects—whether it’s creating intricate decorative pieces or building structural components. This versatility makes them invaluable for crafting, prototyping, and industrial applications.

Compared to manual cutting tools, using a router bit for foam is significantly faster, especially for repetitive cuts or large pieces. CNC routers can operate autonomously once the cut path is programmed, reducing the overall time spent on each project.

Melting can occur due to excessive friction when using a router bit on foam. This results in rough, uneven cuts.

Solution: Reduce the spindle speed and use cooling techniques like compressed air to avoid melting. Compression bits can also help by reducing the amount of friction during the cut.

Foam tear-out can occur when the router bit pulls pieces of foam away rather than cutting cleanly through it. This is more common in softer foams or if the feed rate is too slow.

Solution: Using sharper bits and maintaining a consistent feed rate can help minimize tear-out. Up-cut bits are particularly helpful as they pull material away and reduce tear.

Foam can cause rapid wear on router bits, particularly if they are not properly cleaned after use.

Solution: Clean bits after every use to remove foam residue, and consider using carbide-tipped bits that offer greater durability compared to standard steel bits.

Yes, standard wood router bits can be used to cut foam. However, the key is to select the right type of bit—straight bits or ball nose bits are particularly good for foam cutting.

The spindle speed for foam should be moderate, generally around 12,000 RPM, to avoid generating too much heat that could melt the foam.

Use a lower spindle speed, apply cooling techniques like compressed air, and consider using compression bits to reduce friction during the cut.

Ball nose bits are ideal for detailed foam carving, as they produce smooth, rounded contours with minimal tear-out.

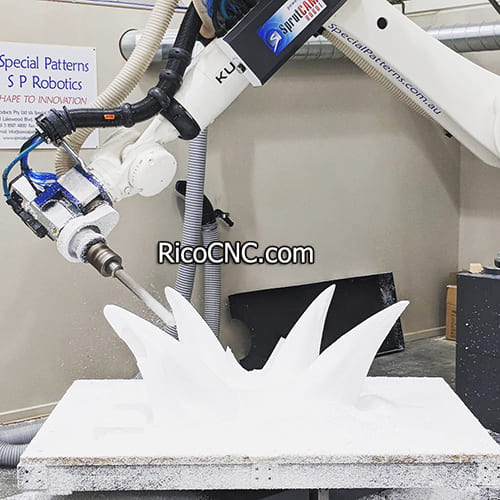

Yes, CNC routers are excellent for cutting foam, especially when precision and consistency are required. The use of CNC automation reduces manual labor and enhances accuracy.

In conclusion, using a router bit to cut foam is not only possible but can be highly effective with the right setup and approach. The ability to achieve precision, versatility in design, and time efficiency makes router bits a popular choice for both hobbyists and professionals. Choosing the appropriate bit type, setting optimal spindle speeds, and employing cooling techniques are essential factors for achieving clean and precise cuts. To get the most out of your foam cutting projects, consider leveraging CNC components like servo motors and solenoid valves, which can help enhance the performance and reliability of your router.

RicoCNC can supply a series of foam bits, like ballnose foam bits, flat end foam bits, conical foam bits, EVA foam bits, EPS Foam Surface Planing (Bottom Cleaning) Router Bit

If you need them, please feel free to contact us.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665