When using the circular saw, wood board chipping is inevitable. Here are 5 common reasons for edge chipping that you should know:

1. Excessive circular saw blade vibration

During operation, if the saw blade vibrates significantly, it is usually related to uneven or poor contact between the drive shaft and the beam saw machine body. The vibration will be transmitted to the entire machine, resulting in abnormal noise. Under normal cutting conditions, the machine should run smoothly without any harsh cutting sounds.

2. Damaged bearings

During long-term operation, bearings can be damaged due to vibration, dust, or wear of the rubber retaining ring outside the bearing.

How to check: You can determine this by listening to the sound when starting or stopping the machine.

3. The shaft has a certain degree of bending during use.

Workers sometimes don't understand the direction of the saw blade when disassembling it, or they don't remove the hexagonal wrench from the main saw in time after installing the saw blade, leading to shaft deformation.

4. The influence of different materials.

When cutting melamine boards, thicker boards (2.5cm, 5cm) have greater resistance to the saw blade. In this case, the saw blade needs to be adjusted lower to reduce vibration and prevent chipping.

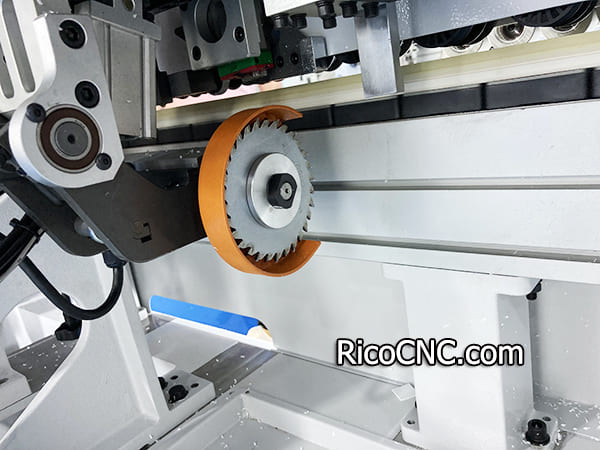

5. Reasons of the scoring saw.

The board is warped, causing the scoring saw to not contact the board; the scoring saw is raised too high, and the vibration affects the cutting; the scoring saw is not sharp; the scoring saw and the main saw are not on the same line; the angle between the scoring saw, the main saw, and the ground is inconsistent, causing excessive resistance and leading to chipping.

If you have any further questions about saw blades, welcome to contact us.

RicoCNC can supply a wide selection of spare parts for woodworking machines, including beam saw parts, CNC machine parts, edge bander parts, etc.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665