Under the "Made in China 2025" strategy, China's manufacturing sector is rapidly advancing toward digitalization, networking, and intelligent transformation. As core equipment in modern manufacturing, the level of intelligence in CNC machine tools directly impacts the overall competitiveness of the industry.

With the deep integration of next-generation technologies like industrial internet, big data, and artificial intelligence, CNC machine tool management and maintenance are undergoing unprecedented changes—shifting from traditional reactive repairs to predictive and intelligent maintenance. This transformation provides strong technical support for high-quality development in manufacturing.

Intelligent Development Trends and Challenges of CNC Machine Tools

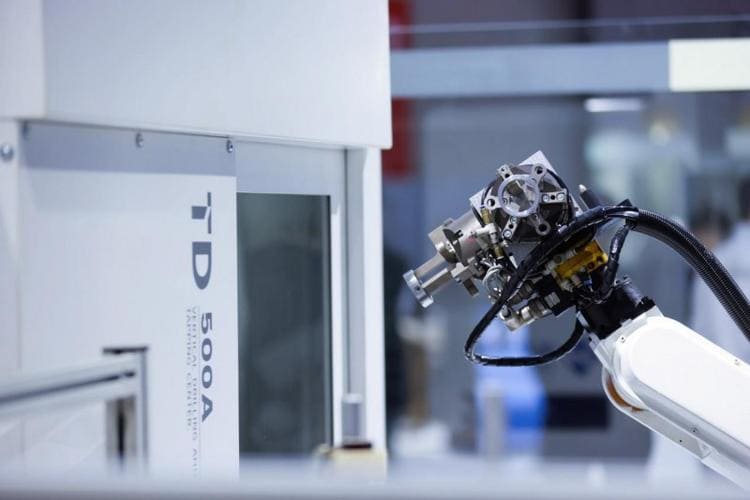

CNC machine tools are a kind of high-tech equipment, which combines a variety of advanced technologies such as mechanical manufacturing, computer control, automatic drive and intelligent detection. Due to the complex structure and high precision requirements, it is very important to manage these equipments well. In today's intelligent manufacturing, the operation, machining accuracy and service life of machine tools directly affect the productivity and product quality of factories.

However, in the past, managing these machine tools mainly relied on manual inspection, regular maintenance and repair when broken. This method is not only inefficient, but also encountered unexpected failures are often caught unawares, which can easily lead to production stoppages and losses.

Now, as factories demand more and more stability and efficiency in the use of equipment, the traditional management methods must be upgraded. It is good that the development of new technologies such as IoT, big data and artificial intelligence has brought intelligent solutions to machine tool management. These technologies can monitor the status of equipment in real time, warn of failures in advance, analyze problems intelligently, and also optimize the maintenance plan, which reduces maintenance costs and improves productivity.

Three Key Technologies to Promote Intelligent Upgrading of CNC Machine Tool Management

1. Remote Monitoring and Predictive Maintenance of CNC Machine Tools Based on Internet of Things

The application of Internet of Things (IoT) technology enables the operational data of CNC machine tools to be collected in real time and transmitted to a cloud-based platform. By deploying various types of sensors (e.g., vibration, temperature, current sensors, etc.), the operating status of the machine tool can be comprehensively monitored, including key parameters such as spindle speed, feed speed, tool wear, etc. Combined with edge computing and cloud computing technologies, this data can be analyzed in real time to detect abnormalities and trigger an early warning mechanism to achieve Predictive Maintenance, PdM. For example, when abnormal spindle vibration is detected, the system can automatically indicate possible bearing wear risks and suggest a maintenance plan, thus avoiding production stoppages caused by sudden failures.

2. Big data analysis optimizes equipment health management and fault diagnosis

CNC machine tools generate massive amounts of data during operation, including machining parameters, equipment status, fault records, and so on. Traditional data analysis methods are difficult to mine the deep value of these data, and big data technology (such as Hadoop, Spark, etc.) combined with machine learning algorithms can deeply mine these data to establish equipment health assessment models. For example, by analyzing historical failure data, it is possible to identify failure modes under specific operating conditions and predict the types of failures that may occur in the future. In addition, big data analysis can optimize machining parameters to improve machining accuracy and tool life, thereby reducing production costs.

3. Artificial Intelligence Enabling Intelligent Diagnosis and Autonomous Decision Making

Artificial Intelligence technologies, especially Deep Learning and Reinforcement Learning, are driving the CNC machine tool management to a higher level of intelligent development. AI-based fault diagnosis systems can analyze vibration signals, acoustic emission signals, and other data to automatically identify the type of fault (e.g., broken tool, spindle imbalance, etc.) and give repair recommendations. Further, combined with Digital Twin technology, it can simulate the operating state of a machine tool in a virtual environment, predict potential problems in advance, and optimize maintenance strategies. In the future, with the maturity of the autonomous decision-making system, CNC machine tools can even automatically adjust the processing parameters according to the real-time working conditions, realizing true “adaptive manufacturing”.

Intelligent management and maintenance of CNC machine tools is an important part of intelligent manufacturing and a key link in improving the competitiveness of the manufacturing industry. The integration and application of technologies such as the Internet of Things, big data and artificial intelligence can not only improve the reliability and productivity of equipment, but also reduce the cost of operation and maintenance, and promote the development of manufacturing in the direction of more efficient and smarter. In the future, with the further maturation of 5G, edge computing, digital twin and other technologies, the management mode of CNC machine tools will be more intelligent and automated, providing a solid technical guarantee for the realization of the strategic goal of “Made in China 2025”.

Rico will follow up on the three major technologies of Internet of Things, Big Data Analysis and Artificial Intelligence to discuss in depth their specific applications in the management and maintenance of CNC machine tool equipment and provide the industry with intelligent upgrading solutions that can be drawn upon.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665