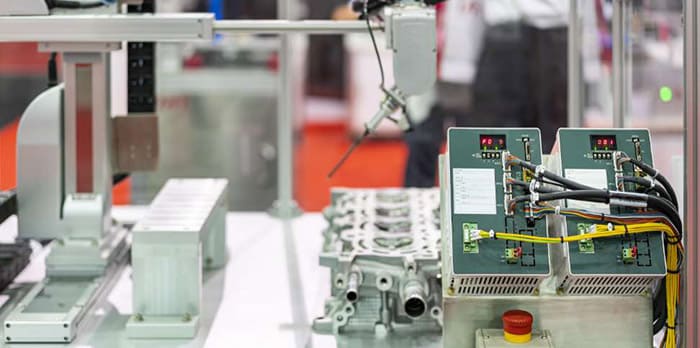

What is a CNC Servo Drive

Modern CNC machines predominantly use CNC servo drives, which consist of a servo drive unit and a servo motor. Servo systems are categorized as either semi-closed-loop or closed-loop systems. Compared to traditional stepper motors, servo motors are equipped with measurement feedback devices, offering advantages such as high positioning accuracy, superior efficiency, rapid response, and smooth transitions between minimum and maximum speeds. If a fault occurs in the CNC servo drive or servo motor, the drive's display will show a corresponding alarm code.

CNC Servo Drive Troubleshooting

Generally, if a CNC servo drive triggers an alarm immediately upon power-up, it is likely that the drive has burned out. If the alarm occurs during operation or after being powered on for some time, the issue is more likely caused by external factors.

While servo drive alarm codes are not 100% accurate, they provide valuable guidance for maintenance personnel. During repairs, careful analysis is essential, and the principle of "from external to internal" should be followed. Regardless of the fault, the following aspects should be thoroughly examined:

1. Check Parameter Settings

System and Drive Parameters: Ensure that the CNC system and servo drive parameters are correctly configured, including motor model, encoder type, and control mode. Incorrect parameters may prevent the drive from functioning properly.

Electronic Gear Ratio: If the electronic gear ratio is set too high, it may cause abnormal motor operation, such as unstable speed or overload.

2. Inspect Power Supply and Circuits

Power Voltage: Use a multimeter to verify that the input voltage is within the drive's acceptable range (e.g., 3-phase 380V or single-phase 220V). Unstable, excessively high, or low voltage can impair performance.

Circuit Connections: Check for secure connections in power and encoder cables, as well as any open or short circuits. Loose wiring may lead to signal loss or drive alarms.

3. Examine Motor Condition

Insulation Performance: Use a megohmmeter to measure the insulation resistance between motor windings and ground. Poor insulation (e.g., due to moisture or damage) can cause leakage or short circuits.

Motor Integrity: If the drive operates normally but the motor does not, internal faults such as burnt windings or seized bearings may be the cause.

4. Runtime Fault Diagnosis

Parameter Mismatch: If faults occur only during operation, the drive and motor parameters (e.g., rated current, speed) may be mismatched—recheck and adjust as needed.

Pulse Command Frequency: Excessively high pulse frequencies from the system may exceed the motor's response capability. Reduce the frequency or confirm the drive's compatibility.

Acceleration/Deceleration Time: If set too short, these can cause motor overload or vibration. Increasing the time constants may resolve the issue.

Gain Parameter Tuning: Vibration or overshooting (e.g., inaccurate positioning) may stem from improper gain settings (e.g., proportional gain, integral time). Optimize these parameters incrementally.

5. Additional Considerations

Environmental Factors: Ensure proper drive cooling, as overheating may trigger protective shutdowns.

Interference Issues: Strong electromagnetic interference can disrupt signals. Separate power and signal cables, and install ferrite filters if necessary.

By systematically following these steps, most common faults can be identified and resolved. If the issue persists, contact the equipment manufacturer or a professional technician for further diagnosis.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665