1. Leverage Spare Tool Stations for Zero-Downtime Tool Change

Modern Brother CNC machines feature intelligent tool management systems. For tools with notoriously short lifespans–think small drills, engraving tools, or specific inserts (like Tool T2 in your setup)–the machine automatically stops when its pre-set "life" counter decrements to zero, necessitating operator intervention to physically replace the expended tool. This forces downtime.

Every manual tool change stops production, impacting your overall equipment effectiveness(OEE). With frequent changes for short-life tools, this accumulates significantly.

Your Brother machine's tool magazine often has spare capacity. Utilize this! You can proactively pre-install identical spare tools–say, "T21" as a backup for "T2"–right alongside the active one. Crucially, you also pre-set the tool length compensation and its lifespan during setup or while another tool is running.

When tool T2 does reach its lifespan, the machine doesn't stop. Its sophisticated scheduler instantly recognizes the spare T21 is available, with the correct offsets and life pre-programmed, and seamlessly calls it into action. Production continues without the costly interruption for manual changeover. This simple planning step translates directly to reduced unplanned downtime and higher spindle utilization.

2. Slash Cycle Times with Proprietary G100: Simultaneous Motion & Tool Change

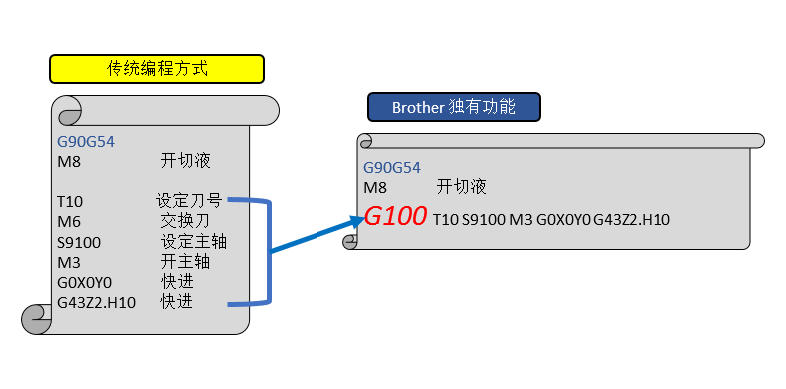

Standard CNC programming dictates sequential actions: the machine might move axes (X, Y, Z) to a tool change position, then change the tool, then move axes to the next machining position. All those stops and starts add up.

This sequential nature inherently bakes non-cutting time into your cycle.

The Brother Breakthrough: Enter G100–Brother's exclusive high-speed synchronous motion command. G100 allows the machine to combine multiple complex actions into a single, smooth, overlapping movement.

Think of G100 intelligently orchestrating tasks like: Simultaneously moving the spindle head along the X, Y, Z axes to the next target position while at the same time rotating the B-axis (if applicable) and concurrently executing a tool change from the magazine.

Consider Brother's internal testing: commanding the spindle to move from its home position to a machining point while also performing a tool change. Traditional G-code required 2.5 seconds for this sequence. Using G100 slashed it to just 1.9 seconds. That's 0.6 seconds saved per tool change.

How many tool changes occur during the machining of one of your parts? Multiply that 0.6-second saving per change. Over thousands of parts, the accumulated time reduction (and therefore, throughput increase) becomes truly substantial.

3. Revolutionize Tapping: The High-Speed G77/G78/G277/G278 Threading Family

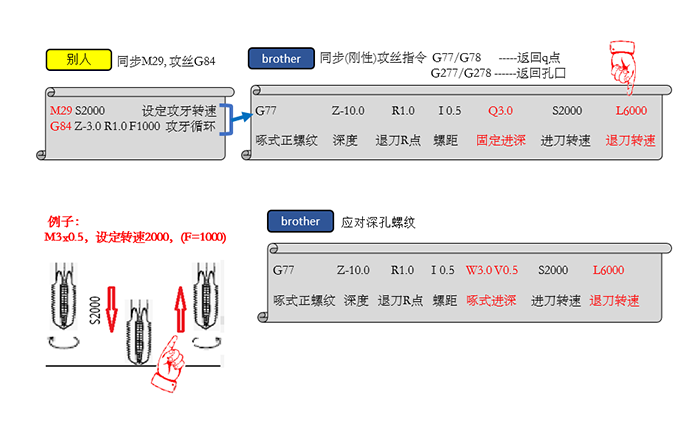

Tapping threads can be a bottleneck. Conventional methods using commands like M84 require you to manually specify both Spindle speed (S) and Feed rate (F). Calculating F correctly demands you to derive it precisely from the thread's Pitch (I), a step prone to human error with potential scrap consequences.

Old Way Hassles: Calculating feed from pitch manually introduces unnecessary risk and setup time. Furthermore, the retract phase (pulling the tap back out of the hole) doesn't involve cutting. Yet, most machines are limited–they can tap forward at, say, S2000 RPM, but must retract backwards at the same slow S2000 RPM, wasting time.

Brother tackles both inefficiencies head-on with its advance G77,G78, G277, and G278 tapping commands.

Just input the Spindle Speed (S) and the actual Thread Pitch (I). The control's firmware automatically calculates the correct synchronized feed (F), eliminating manual calculation errors and saving programming time.

Brother machines have the electromechanical muscle to exploit the non-cutting retract phase. You can directly command aggressive reverse spindle speeds. For example: Tap into the hole at S2000 RPM, but then retract outat a much faster S6000 RPM. This dramatically reduces the "air-cutting" time per tapped hole, significantly improving tapping cycle times.

For demanding materials or deeper threads, add the WV parameter. This initiates a decreasing-pass strategy (sometimes called "peck" or "progressive" tapping). Instead of one full-depth pass, it retracts slightly at predetermined points within the hole during the cutting phase.

Breaks chips efficiently, preventing chip packing and breakage.

Reduces torsional load and heat buildup on the tap.

Significantly extends tap life.

While the visible capabilities (such as the S6000 retract speed) are impressive, the real mystery of achieving such shock-free, stall-free, high-speed forward and reverse rotation lies deep within Brother's proprietary motion control technology: extremely fast spindle acceleration and deceleration speeds (reaching target speeds in as little as 0.2 seconds) and near-instantaneous reversal - the near-zero standstill time between forward and reverse rotation. This electromechanical synergy is the key to reliably achieving these cycle time breakthroughs.

Rico can supply various Brother Machine tools. You can leave your inqjuiry here, or contact us by email.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665