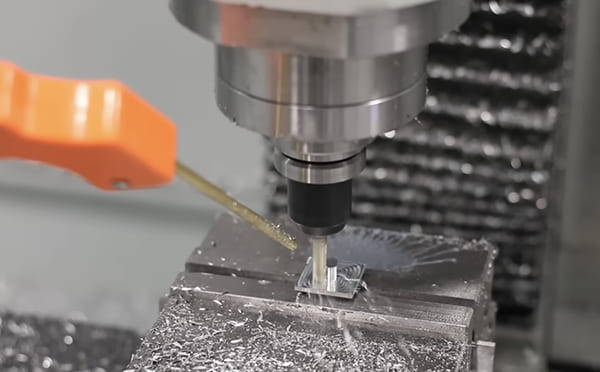

CNC machining centers deliver superior precision, stability, and efficiency compared to manual machines. However, a severe risk exists: tool crashes – where the cutter strikes the workpiece or machine. Often caused by operator error, even minor crashes damage tools and parts, while major ones can cripple machine components and accuracy, leading to costly downtime.

Preventing these collisions is paramount for safety and protecting your investment. As a manufacturer, we see these issues frequently. The good news? Most are preventable. Let's examine the top 5 operator-caused reasons for tool crashes in CNC machining centers and exactly how to avoid them.

1. Failure to Return to Reference Point Upon Startup (Incomplete Machine Coordinate System Establishment)

CNC machining centers powered on, did not make the machine tool axes to return to their respective reference points, the machine tool coordinate system has not been established to carry out other operations will result in tool collision accidents. CNC machining center power start, you must first make each axis are returned to their respective reference points, to determine the machine coordinate system before other operations in order to ensure that the reference point back to the process of tool safety, machining centers back to the reference point of the general Z-axis positive direction of the return to zero, and then the X and Y-axis positive return to zero operation. When the return to the reference point is completed, the display will show the coordinate value of the machine reference point in the machine coordinate system, indicating that the machine coordinate system has been established. Only when the correct machine coordinate system is established can the datum deviation due to various reasons be eliminated.

2. Mismatched Tool Measurements (The Tool Length Trap)

When CNC machining centers need to use more than one tool to complete, usually use tool length compensation to solve the problem of different tool length differences to the impact of processing, the establishment of a common method of tool length compensation is to select the reference tool to set the workpiece coordinate system, and then let the other tool to touch the Z-axis direction of the same height, to find out the other tool and the length of the benchmark tool length of the difference in the direction of the difference between the value of the positive, then it indicates that longer than the benchmark tool, and the difference is negative, then it indicates that the benchmark tool short, the difference is negative, then it indicates that the benchmark tool. If the difference is positive, it is longer than the reference tool, and if the difference is negative, it is shorter than the reference tool. Enter the correct difference value and the positive and negative sign into the corresponding tool length compensation offset number. If the reference tool is damaged during machining, it is necessary to re-establish tool length compensation for all tools. Otherwise there may be accidents such as the tool rushing directly to the workpiece after executing the program, resulting in scrapping of the workpiece and damage to the tool.

3. Improper Recovery After Mid-Program Stop/E-Stop

Machining center execution program during normal processing, due to operator error makes the program stop, if the operator presses “RESET” reset, immediately after the cycle start, this time is easy to cause collision between the tool and the workpiece. Because the default value of the operation and the program set value changes, press “RESET” reset will reset the CNC system to the initial state, clearing the pre-read program information saved in DRAM, will change the tool movement instructions and spindle speed.

In the process of running the program automatically, if the program stops due to mis-stopping, change the mode to editing mode, press “RESET” to reset the program, and then run the program again.

4. Control panel operation

CNC machining center control panel keys and knobs on the operation of the degree of proficiency, will directly affect the frequency of accidents hit the knife. For example: the use of JOG manual mode key to move the spindle or table and incremental feed rate adjustment knob with the use of program operation and feed rate adjustment knob with the use of. When moving the machine spindle and table to control the speed of movement, running a program to process the workpiece also need to control the speed of movement of the machine axes, in order to avoid collision between the tool and the workpiece.

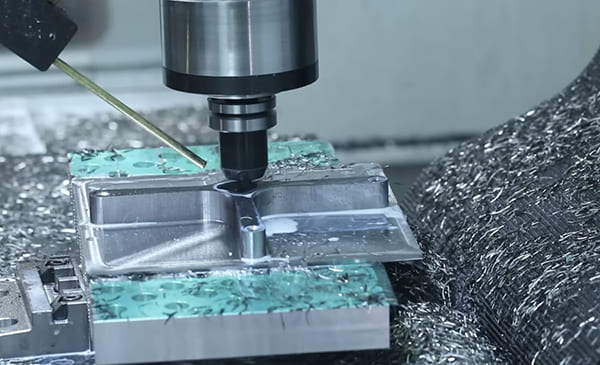

5. workpiece clamping operation

Workpiece clamping is the appropriate way to fix the workpiece to be machined, in order to ensure that the workpiece machining size and its accuracy requirements of the process. However, in the clamping of the workpiece is the most consideration is the positioning and clamping of the workpiece, often ignoring the tool path, resulting in the tool in the process of moving or cutting the workpiece and the platen and clamping elements to interfere, resulting in tool collision. Therefore, in the process of clamping and positioning the workpiece, we should consider the movement of the tool and the tool path to avoid collision between the tool and the clamping element.

Through the above points of the reasons for collision can be seen CNC machining center machine tool as a high-precision machine tool, anti-collision is very necessary. Therefore, the operator is required to develop careful and cautious operating habits, according to the correct method of operation of the machine tool to reduce the occurrence of machine tool crash phenomenon. With the development of technology appeared in the machining process tool damage detection, machine tool anti-collision detection, machine tool adaptive machining and other technologies, these can better protect the CNC machine tool.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665