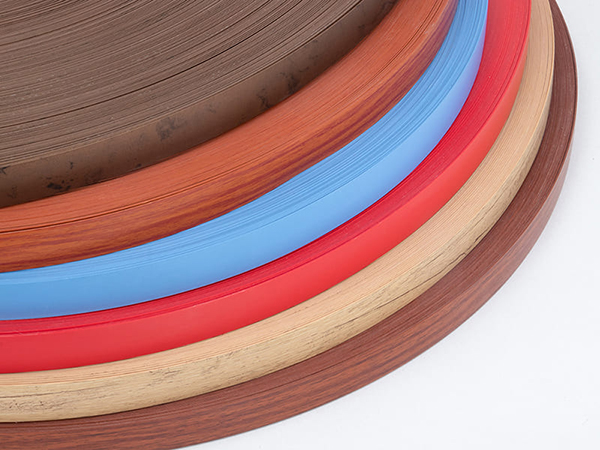

Edge banding is an extremely important step in the production of panel furniture. Different edge banding materials are used for edge banding. The following are 6 common edge banding tapes on the market.

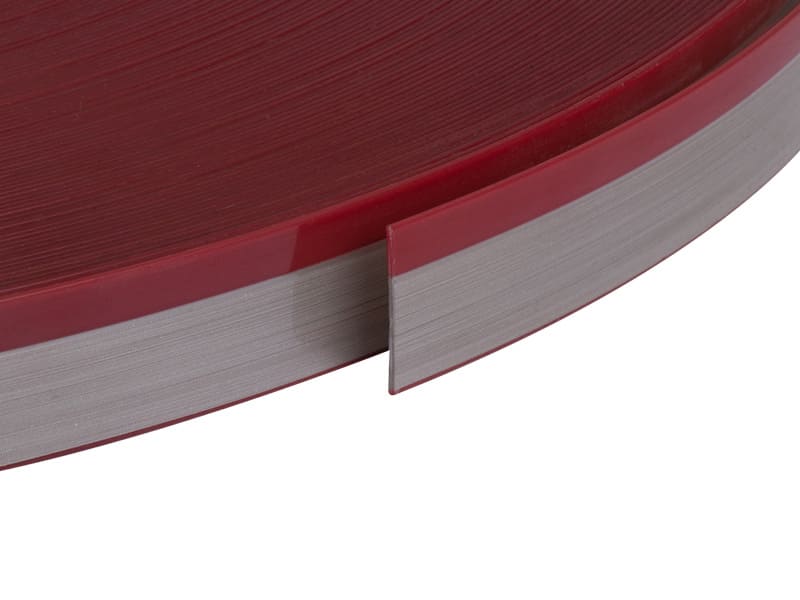

1. PVC edge banding tape

PVC edge banding tape is made of polypropylene or polyvinyl chloride and can be processed into wood grain, solid color, and two-color. The appearance includes wood grain, marble, cloth grain, etc., with the realism and three-dimensional sense of wood.

Edge banding PVC tape is one of the most common edge banding materials and is widely used because of its low price, rich colors, wear resistance, and durability.

Advantages:

• Affordable and economical.

• A variety of colors and patterns are available.

• Good wear resistance and long service life.

Disadvantages:

• Poor environmental performance, some low-end products may contain harmful substances.

• Aging may occur after long-term use.

2. Solid Wood edge banding tape

Wood edge banding tape is made of natural wood veneer. Because it uses natural solid wood, the edge banding is environmentally friendly and healthy, without too many chemical pollutants.

For example, there are birch, oak, etc. Many furniture pieces use this type for edge banding strips, but the price is high.

Solid wood veneer edge banding is made of solid wood veneer as the main raw material. This type of edge banding tape will be pasted with non-woven fabric on the back to increase the strength of the veneer and prevent the veneer from cracking. Because it is made of natural veneer, the texture effect and texture are natural and real, with a variety of varieties, patterns, and colors.

Advantages: good edge sealing effect, soft and not easy to deform, strong environmental protection performance, can be harmoniously unified with the board surface material, convenient and fast processing, high utilization rate, etc.;

Disadvantages: weak moisture resistance, due to the high cost of raw materials and high production process cost, the overall price is high.

3. Melamine edge banding tape

Melamine edge banding tape is based on paper printed with various wood grains, leather, and stone grains, and then impregnated and solidified with modified melamine resin to form paper edge banding. There are also metal edge bandings, but the usage rate is not very high.

Commonly known as paper edge banding, its advantages are easy to stick and not easy to expand and deform when cold or hot. However, due to its brittleness and easy folding, it is easy to be damaged during furniture production and transportation.

4. ABS edge banding tape

ABS edge banding tape is an environmentally friendly edge banding material, the main component of which is acrylonitrile-butadiene-styrene copolymer. ABS resin is one of the most advanced materials in the world. During processing and manufacturing, fewer additives are added, and the rounded corners after trimming are very smooth and bright, with good gloss.

Advantages: wear-resistant, corrosion-resistant, aging-resistant, fire-resistant, moisture-proof, green and environmentally friendly, strong impact resistance, sustainable and recyclable, etc.

Disadvantages: The production cost is relatively high, and the price is about 1 time higher than that of the same PVC edge banding tape.

5. Aluminum alloy edge banding tape

Aluminum alloy edge banding tape is made of aluminum alloy metal as the main raw material. Because it is made of metal, it has the unique texture and luster of metal.

Advantages: strong and durable, no cracking, not easy to deform, scratch-resistant, corrosion-resistant, weather-resistant, long service life, good flexibility, more environmentally friendly;

Disadvantages: poor matching effect with the wood grain finish of the board, difficulty in being harmonious, and lack of design aesthetics.

6. Acrylic edge banding tape:

Acrylic edge banding tape is a high-end edge banding material, the main component of which is polymethyl methacrylate.

Advantages:

• High transparency, good visual effect, suitable for high-end furniture.

• Good weather resistance, not easy to turn yellow after long-term use.

• Excellent edge banding effect, smooth and flat joints.

Disadvantages:

• Expensive and high cost.

• High processing technology requirements, and professional equipment required.

RicoCNC is a company dedicated to providing woodworking machinery accessories, including CNC machine parts, edgebanding machine parts, CNC beam saw parts, moulder spare parts, etc. We have been deeply involved in the woodworking industry for many years and have rich experience. We have a complete range of woodworking machine parts and our parts are shipped all over the world with fast delivery. If you need more information, please contact us.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665