What is a CNC Tool Magazine?

A CNC tool magazine is a storage device integrated into CNC machining centers, designed to automatically change tools during machining processes. By enabling automated tool switching, it reduces production costs, shortens processing times, and enhances efficiency in operations such as milling, drilling, boring, and tapping. This article clarifies the types and features of tool magazines.

Types of Tool Magazines

Tool magazines are devided into two types based on their structure: Chain Tool Magazinesand, Carousel-Type Tool Magazines, Disc-Type Tool Magazine, Umbrella Chain Type Magazine, and Horizontally mounted type magazine.

Chain Tool Magazine

Chain tool magazines are capable of storing a large number of tools, typically exceeding 20 and sometimes up to 120 or more. They feature a simple, fast, and reliable structure. Due to their high customization potential, chain-type magazines are generally more expensive. Tools are transferred via a chain mechanism to the desired position, where a robotic arm installs them onto the spindle.

It has Chain Type Vertical Magazine and Horizontal Chain Type Magazine two types.

Chain Type Vertical Magazine Feature:

Cylinder cam splitting mechanism, high splitting accuracy, low failure rate.

Compact structure, large capacity, long service life.

Imported engineering plastic knife sleeve, light weight, high strength, not easy to damage.

Double bearing separation knife arm, high concentricity, low noise.

Horizontal Chain Type Magazine Feature:

Cylinder cam splitting mechanism, high splitting accuracy, low failure rate.

Compact structure, large capacity, long service life.

Imported engineering plastic knife sleeve, light weight, high strength, not easy to damage.

Double bearing separation knife arm, high concentricity, low noise.

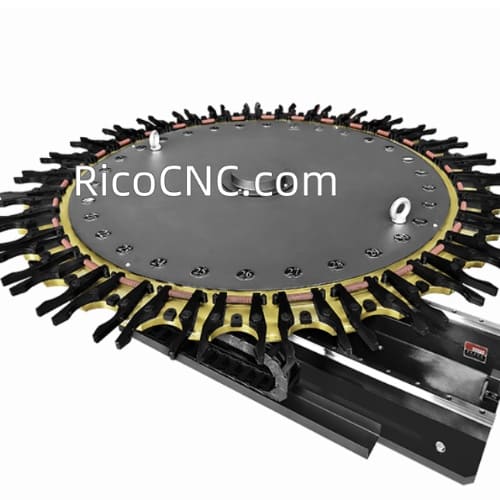

Carousel-Type Tool Magazine

Commonly used in machining centers, carousel-type tool magazines automate tool changes to improve efficiency and minimize downtime. The magazine rotates to position the required tool, which is then swapped into the spindle.

Lightweight, aluminum alloy cutter disc, reducing load.

Adopting Geneva wheel segmentation mechanism, smooth operation, high segmentation accuracy

The cutter disc slides using linear bearings, low friction, long life.

Spring clamp arm, clamping the tool, easy clamping, simple maintenance.

Disc-Type Tool Magazine

Key features include:

Compact Design: Ideal for smaller CNC machines due to their space-efficient footprint. Capacity ranges from 2 to 30 tools.

Fast and Precise Tool Selection: Circular rotation ensures quick and accurate tool positioning.

Low Maintenance: Simple mechanical structure reduces the risk of failure and ensures reliability.

Disc-Type Tool Magazine has two types: Vertical disc type magazine features and Horizontal disc type magazie:

Vertical disc type magazine features:

Cylinder cam segmentation mechanism, high segmentation accuracy, low failure rate.

Simple structure, convenient maintenance, long service life.

Plastic knife sleeve, light weight, high strength, not easy to damage.

Double bearing separation knife arm, high concentricity, low noise.

Horizontal disc type magazie features:

Cylinder cam segmentation mechanism, high segmentation accuracy, low failure rate.

Simple structure, convenient maintenance, long service life

Full-mouth engineering plastic knife sleeve, light weight, high strength, not easy to damage

Bearing separation knife arm, high concentricity, low noise.

Umbrella Chain Type Magazine

Plastic steel knife claw, high rigidity, long life.

Use precision dividers to separate knives, fast speed, high precision.

Easy to connect, easy to assemble, and convenient to maintain.

Horizontally mounted type magazine

Adopt servo motor, high efficiency, high precision(can also be driven by ordinary motor).

The slide seat probe uses linear bearings, which can change the tool positioning accurately and quickly and protect the tool magazine from pollution.

The knife claw group is positioned with a secondary support seat, and the knife is stable and does not shake.

Also you can find Drum-Type Tool Magazine and Arm-Type Tool Magazine Based on Mounting Design

1. Drum-Type Tool Magazine

The most common design, drum-type tool magazines arrange tool pockets around a rotating drum. This design reduces dust and chip contamination by up to 80%, protecting tool tapers. The drum rotates to align the desired tool with the spindle. A variation of this design is the bucket magazine, which uses a similar rotational mechanism.

2. Arm-Type Tool Magazine

Controlled by a servo system, arm-type magazines use linear arms to transfer tools between the magazine and spindle. They offer greater flexibility for handling diverse tool shapes and longer travel distances. However, their complex design increases mechanical intricacy and maintenance requirements.

Tool magazines have become indispensable components in modern CNC machining centers, enabling advanced automation and operational efficiency.

In the woodworking processing center, we usually use chain type tool magazine and disc tool magazine. For these tool magazines, they usually use different brand & type spare parts, RicoCNC supplies a series of tool magazine spare parts, including tool forks, tool holders, tool pots, and more. we offer compatible parts for Deta, SUN, Sanjet, and other major brands. For inquiries, please contact us—we’re glad to help you.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665